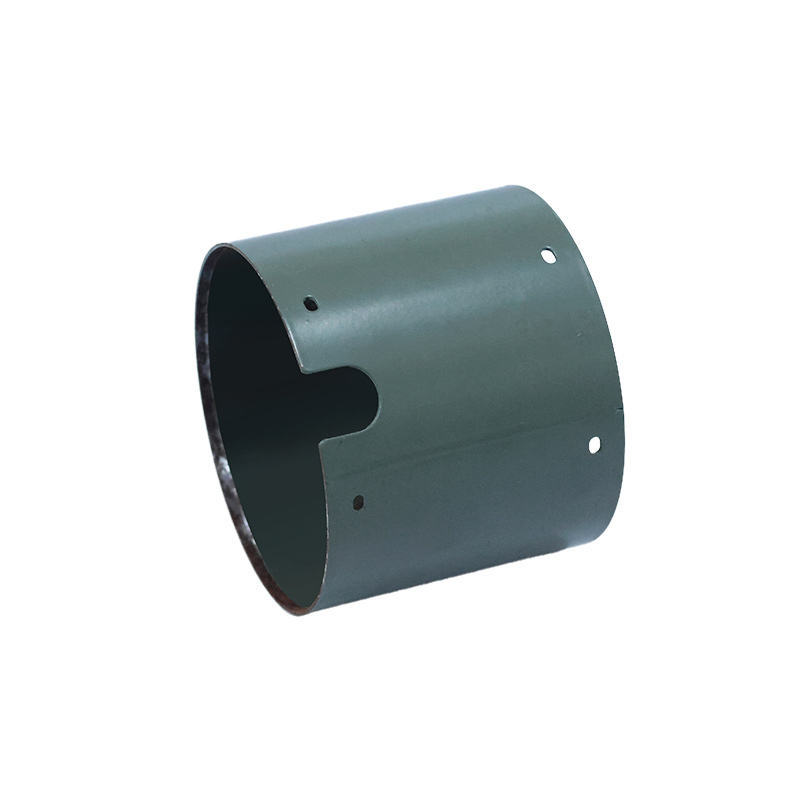

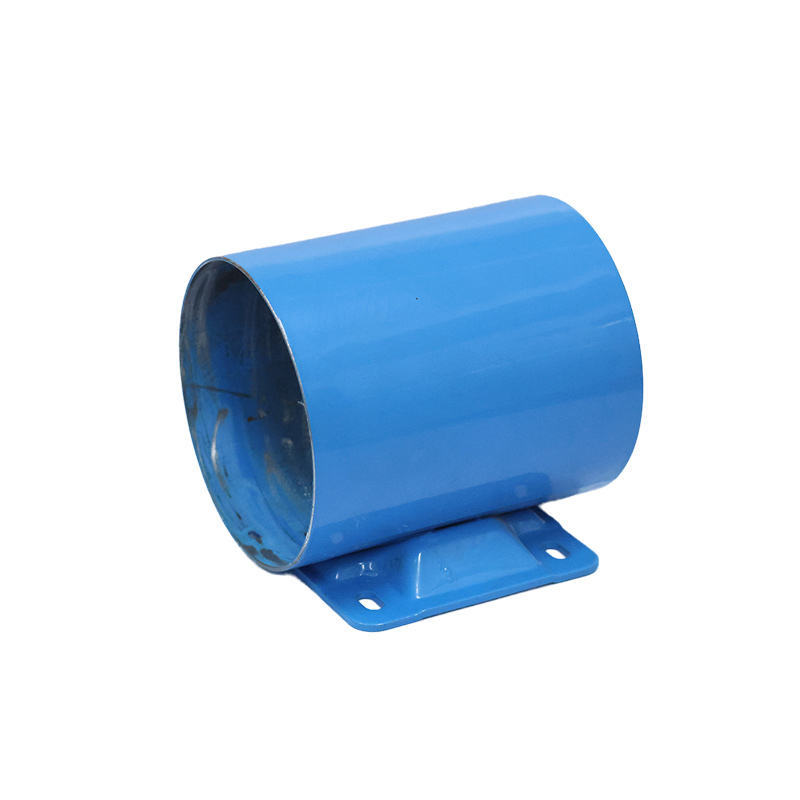

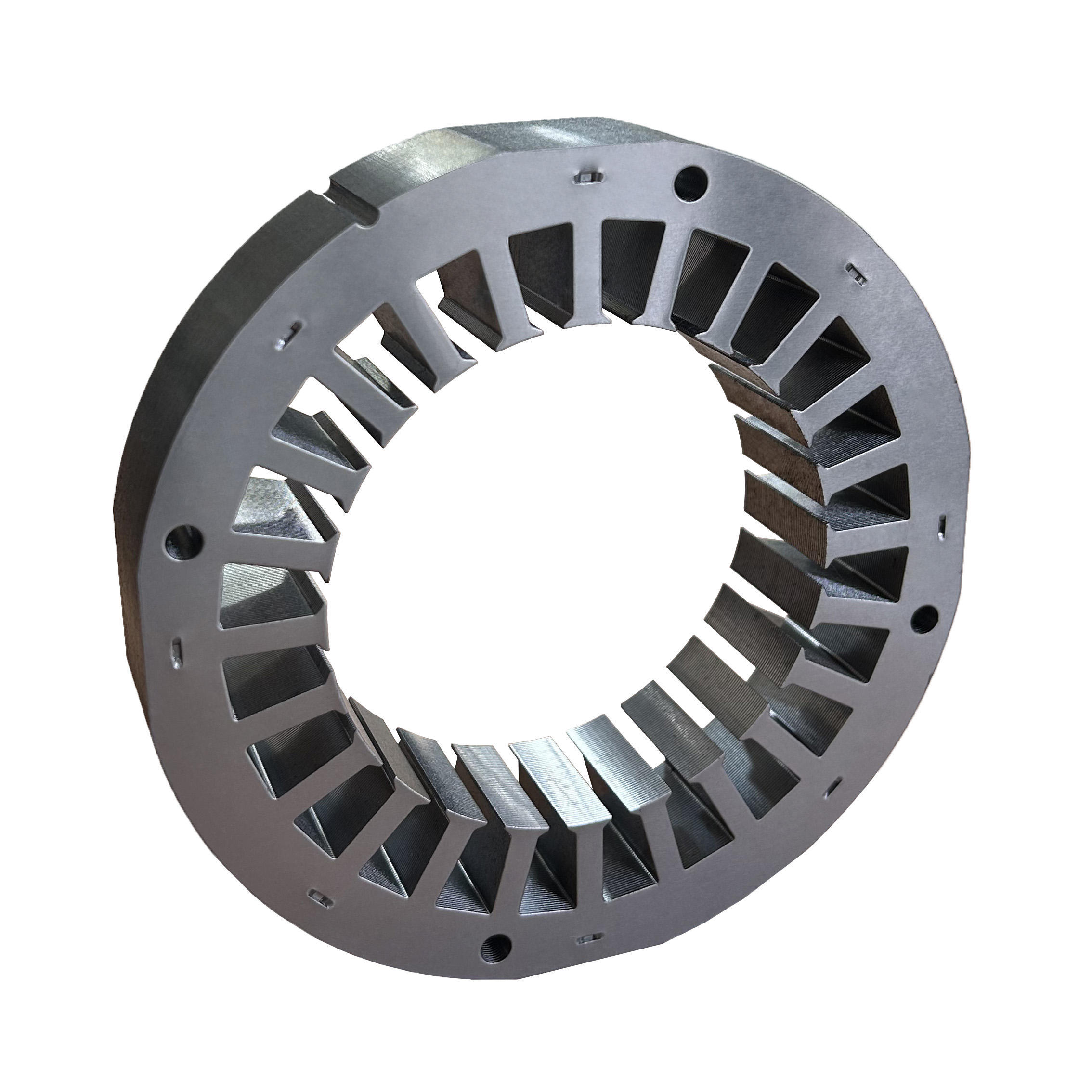

Press-forged aluminum motor parts

Our company mainly engages in various types of motor coils, winding, embedding processing, and has the ability to assemble and manufacture stator assemblies through manual embedding, machine embedding, immersion painting, and so on.

Key words:

Press-forged aluminum motor parts

Classification:

Cast aluminum

E-mail:

Important attributes

Packaging and Shipping Information

Cast aluminum

Aluminum casting is the process of pouring molten aluminum into a mold and allowing it to cool, thereby forming aluminum parts with the desired shape. The castings produced from aluminum casting are referred to as die-cast aluminum components.

Aluminum cast parts are prone to internal defects such as porosity and shrinkage during the casting process. When these flawed castings undergo machining, the dense surface layer is removed, exposing the underlying internal structural imperfections.

The sealing requirements for automotive aluminum casting parts—such as cylinder blocks, cylinder heads, intake manifolds, and brake valve bodies—dictate that even the presence of minute defects like micro-pores during pressure-sealing tests can lead to leakage of the sealing medium, resulting in significant material waste. Often, these flaws are only detected under the test pressures used in manufacturing, leading to substantial inefficiencies in terms of labor time, raw materials, and energy consumption.

To address the high defect rate in aluminum cast parts for automotive applications—preventing costly scrap due to these defects—the production process must incorporate specific measures. Among the most commonly used techniques is penetration treatment, which effectively seals off the defects.

The so-called "penetration" refers to the process of allowing a penetrant to seep into the microscopic pores of cast aluminum components under specific conditions. After curing, the filler material integrates seamlessly with the pore walls, effectively sealing the micro-porous structure of the part to meet the requirements of processes such as pressurization, fluid flow, and leak prevention.

Cast aluminum parts are cost-effective and well-crafted, while their ability to be remelted and recycled helps conserve resources and energy—making this material a sustainable choice for both current applications and future development.

Such as researching and developing cupola-electric furnace duplex melting processes and equipment; widely adopting advanced iron desulfurization and filtration technologies; thin-walled high-strength cast iron manufacturing techniques; composite cast iron material production technologies; surface or localized strengthening techniques for cast iron; isothermal austempered ductile iron technology; as well as specialized casting processes and equipment, including metal casting, sand-coated casting, continuous casting, and other innovative methods.

Product Message

Other Products