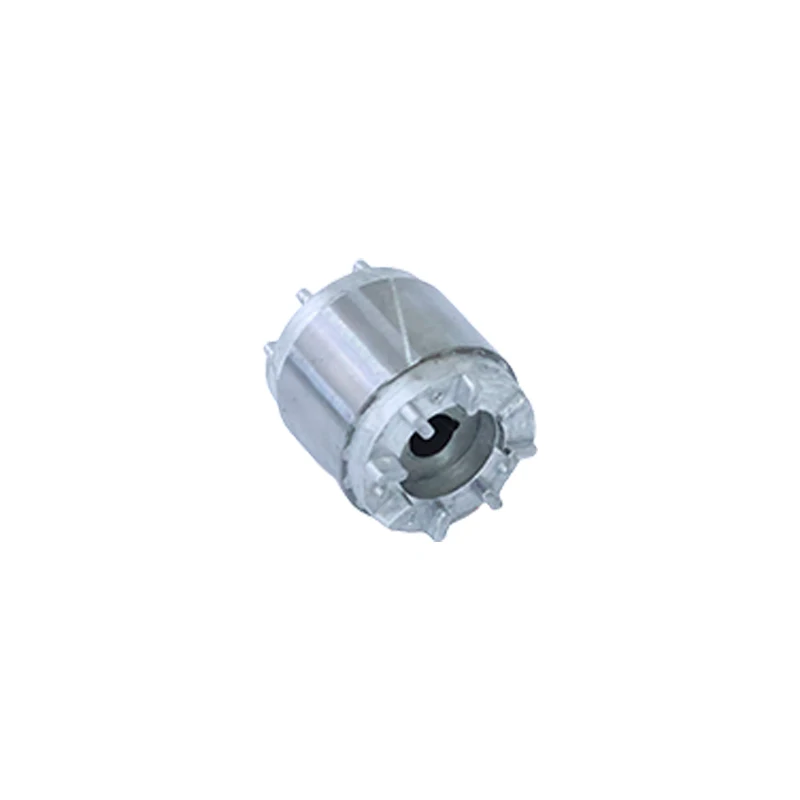

Cast aluminum rotor motor parts

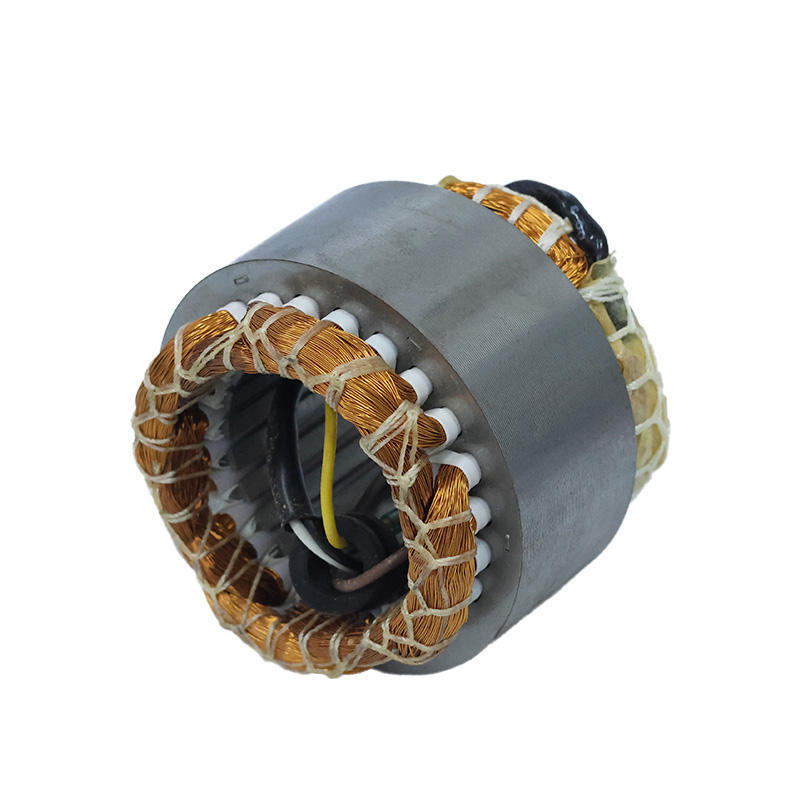

Our company mainly engages in various types of motor coils, winding, embedding processing, and has the ability to assemble and manufacture stator assemblies through manual embedding, machine embedding, immersion painting, and so on.

Key words:

Cast aluminum rotor motor parts

Classification:

Cast aluminum

E-mail:

Important attributes

Packaging and Shipping Information

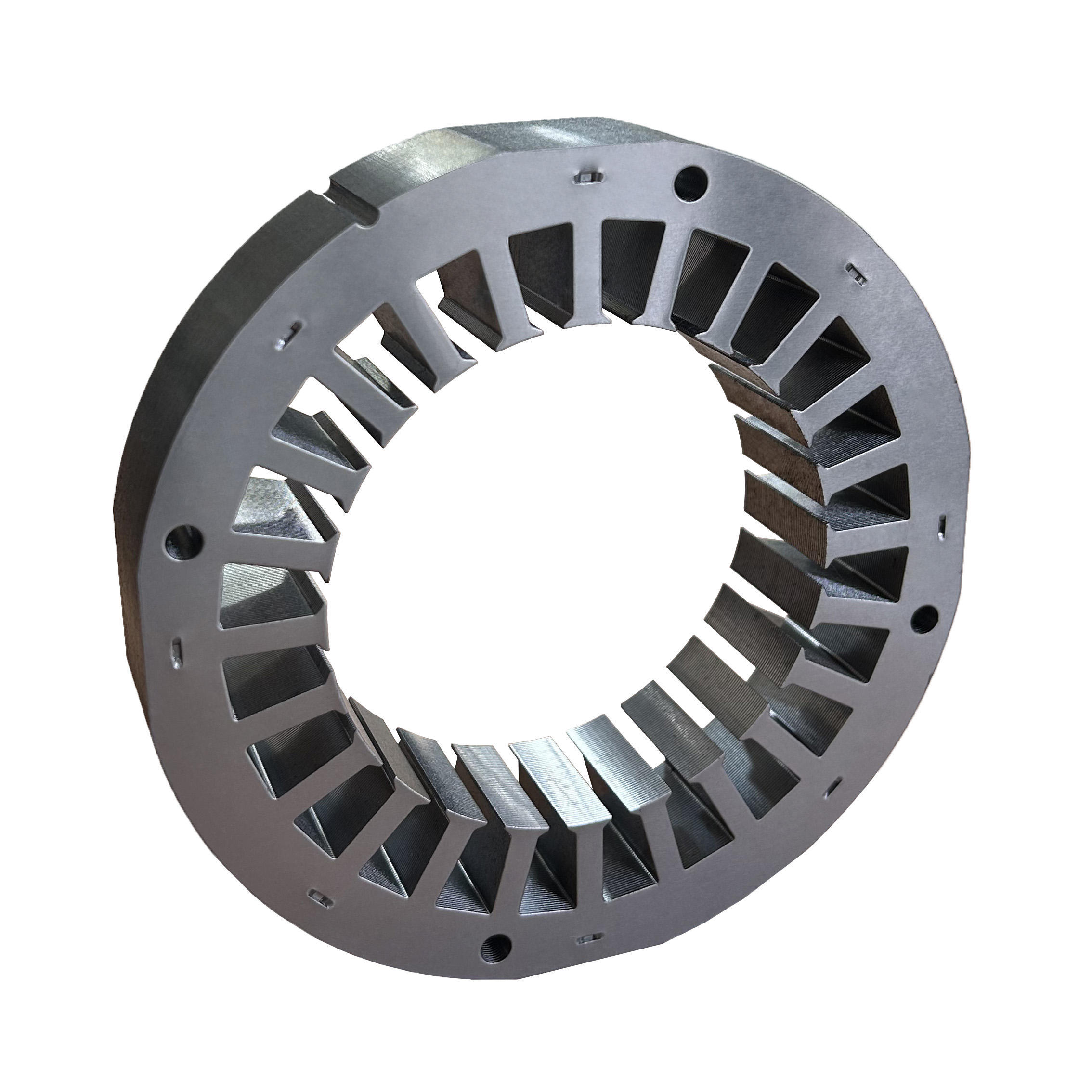

In the core area of industrial motor operation, cast aluminum rotors play a critical role. Our cast aluminum rotors are masterpieces crafted through a variety of precision processes.

Starting with the selection of raw materials, we rigorously control the quality of the aluminum alloy. Its exceptional thermal and electrical conductivity lays the foundation for highly efficient power conversion. Our unique low-pressure casting process ensures that molten aluminum evenly fills the mold cavity under precisely controlled temperature and pressure conditions. As a result, the finished rotor resembles a natural work of art—free from defects such as porosity or shrinkage cavities—and boasts flawless structural integrity.

Through precise CNC machining and carving, dimensional tolerances are tightly controlled within ± [minimum tolerance value] mm, ensuring a perfect fit with the motor stator and guaranteeing a uniform air gap and minimal magnetic reluctance.

During the dynamic balancing calibration process, specialized equipment performs precise adjustments to eliminate even the smallest imbalances.

Eccentricity ensures the motor runs as steadily as a rock, significantly reducing vibration and noise—and creating an even quieter environment.

A more enjoyable work environment.

Eccentricity ensures the motor runs as steadily as a rock, significantly reducing vibration and noise—and creating an even quieter environment.

A more enjoyable work environment.

Product Message

Other Products