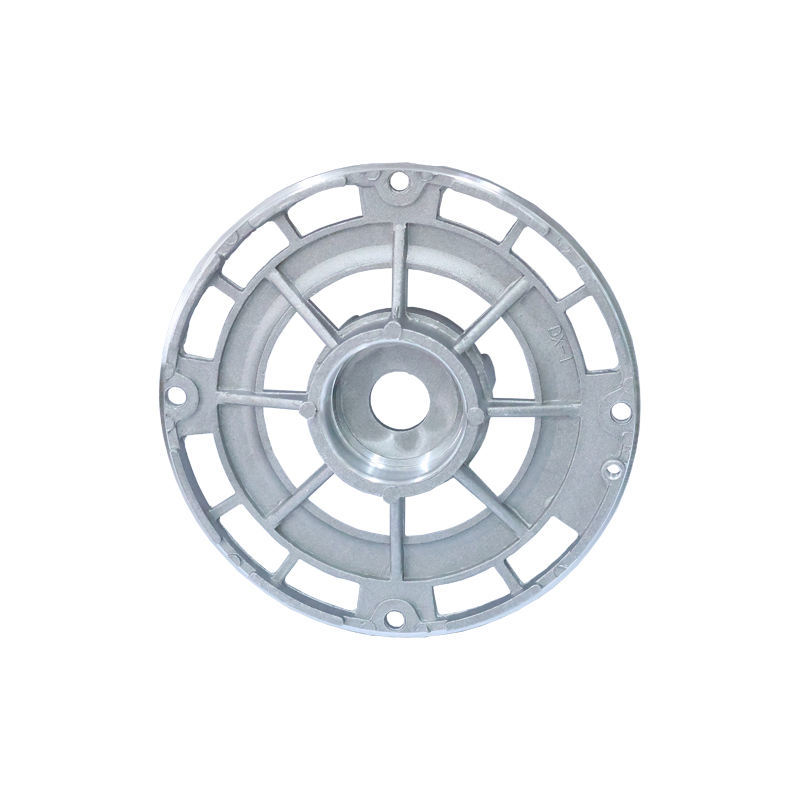

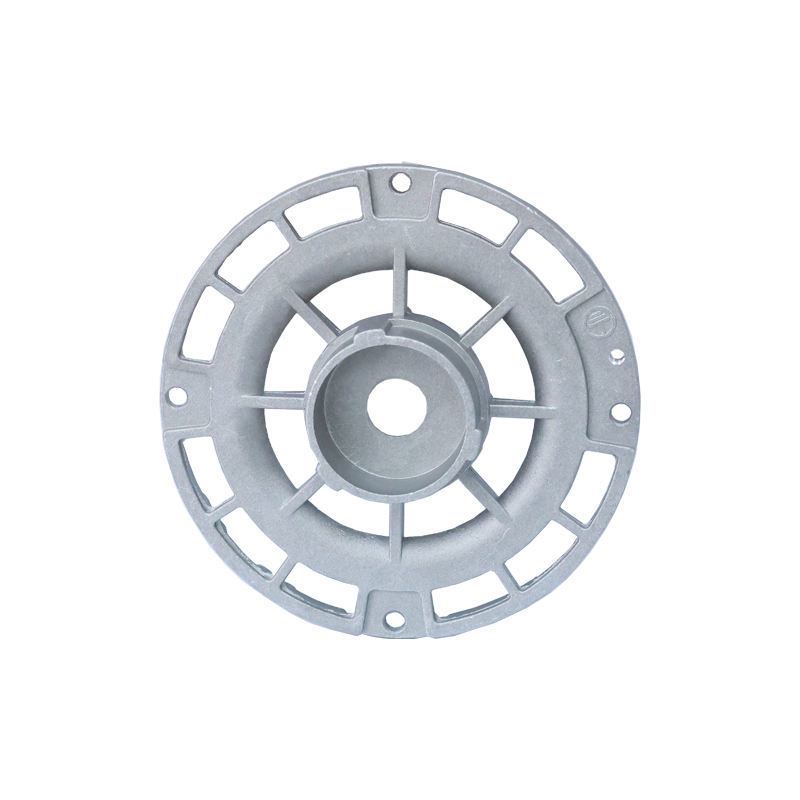

The use of motor end caps

Die-cast motor housing and end caps

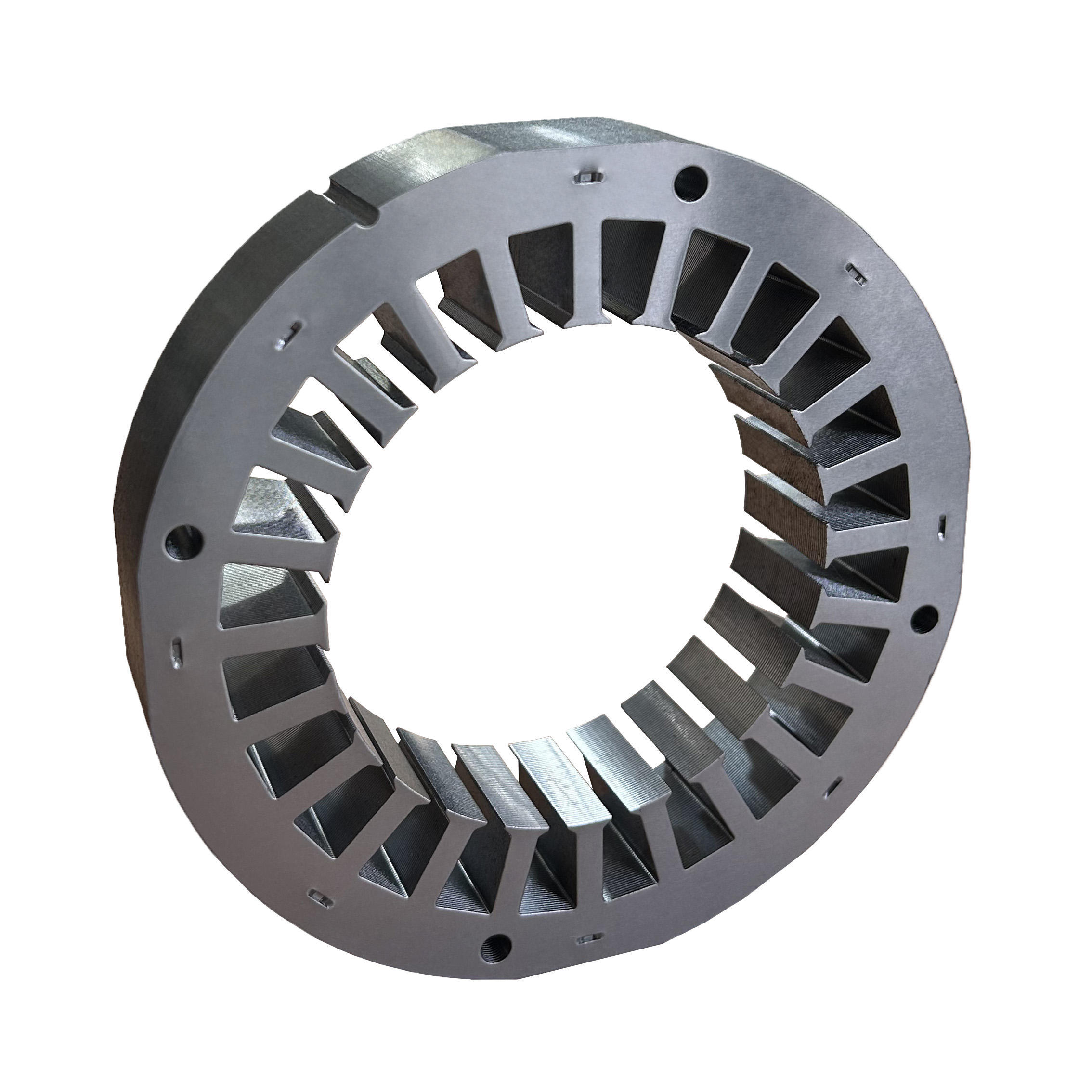

Our company mainly engages in various types of motor coils, winding, embedding processing, and has the ability to assemble and manufacture stator assemblies through manual embedding, machine embedding, immersion painting, and so on.

Key words:

Die-cast motor housing and end caps

Classification:

End Cap

E-mail:

Important attributes

Packaging and Shipping Information

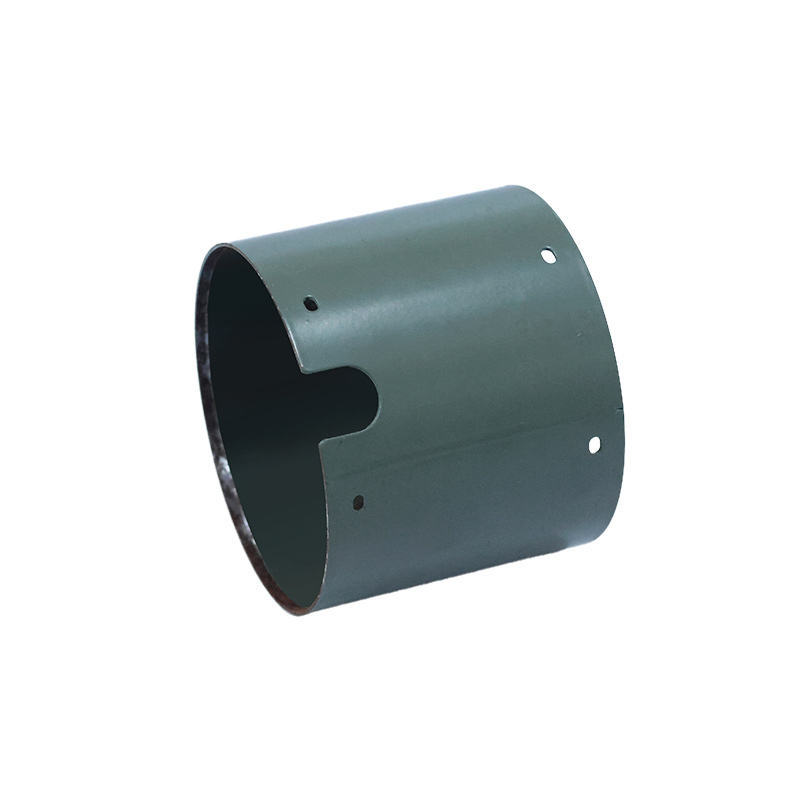

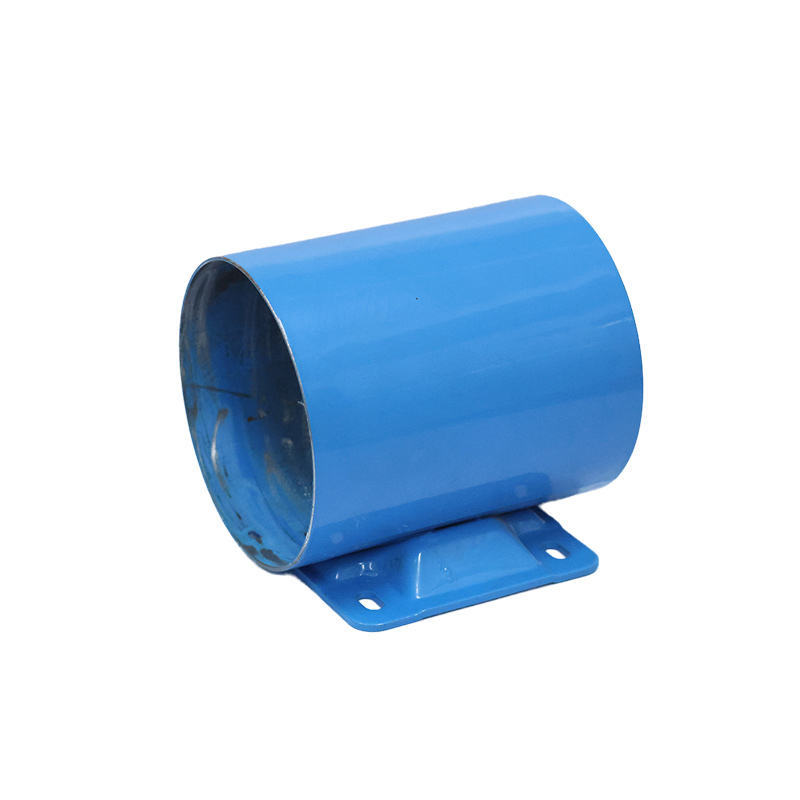

Motor end cover

Motor end caps: These are the covers for the motor housing. Typically divided into front and rear caps, they serve to secure and support the motor rotor shaft. An end cap generally refers to a cover where the axial dimension of the motor is larger than its radial dimension. Its primary function is to define the rotor’s axial position within the motor. Of course, it works in conjunction with different types of bearings and is attached to the stationary motor stator housing via the end cap, ensuring the proper clearance between the rotor and stator. End caps are usually manufactured using cast-iron processes, though smaller motors may also use sheet-metal stamping.

Typically, the front and rear end caps of an electric motor are used to secure the entire motor via the rotating shaft. Motor end caps are essential accessories for motors and are widely employed in various applications—commonly found in scenarios such as automotive air conditioning systems, car fans, heaters, and more. In terms of design, motor end caps usually feature a few recessed or protruding holes.

One is designed to enhance the motor's heat dissipation, while the other aims to improve the motor's mechanical strength.

Most industrial motor end caps are made of cast iron and serve to support the bearings at both ends of the motor.

Its primary function is to secure the motor rotor while also providing cooling. It’s typically made from cast iron, with some variations existing.

Cast aluminum kilowatt motor.

Its primary function is to secure the motor rotor while also providing cooling. It’s typically made from cast iron, with some variations existing.

Cast aluminum kilowatt motor.

Motor end cap material

Motor end caps are typically made from metals such as aluminum, aluminum castings, cold-drawn steel, and plastic wood. The choice of material usually depends on the specific type of motor. For instance, automotive motors often use cold-drawn steel, while large-scale motors typically employ die-cast materials.

Surface Treatment of Motor End Caps

The surface treatment of the motor end cover directly affects the lifespan of the entire motor; typically, the following methods are used:

1. Blackening treatment

2. Galvanizing treatment

3. Painting treatment

4. Dacromet plating treatment

Generally speaking, the blackening process is the worst in terms of cost—and vice versa.

Product Message

Other Products