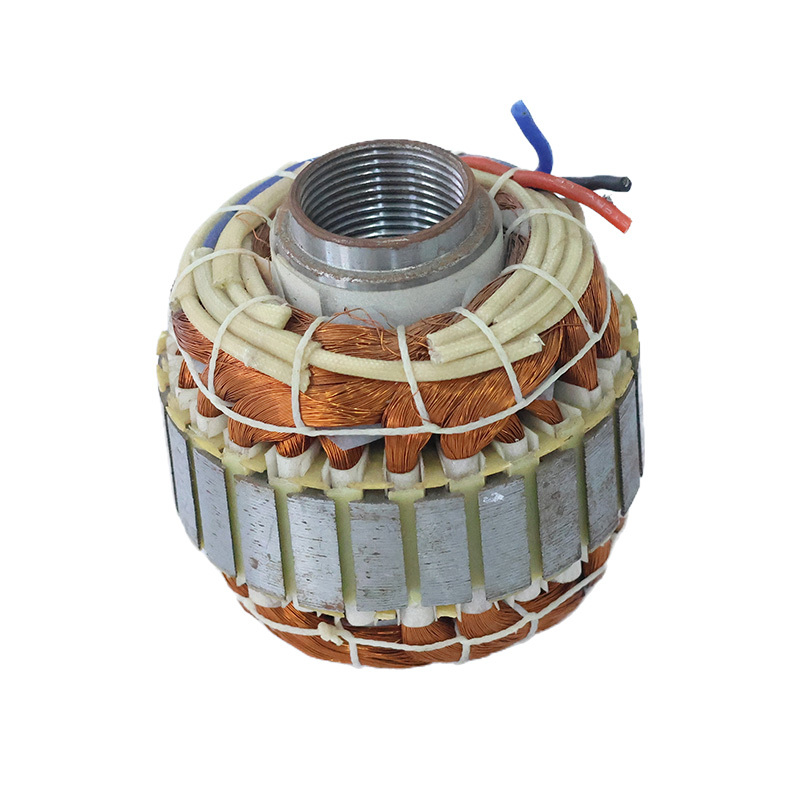

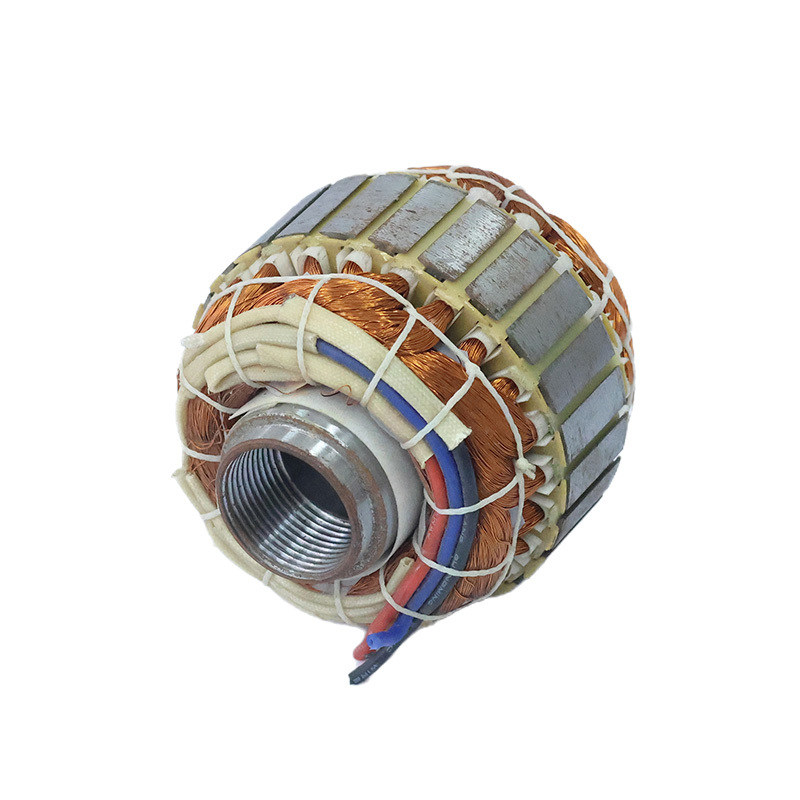

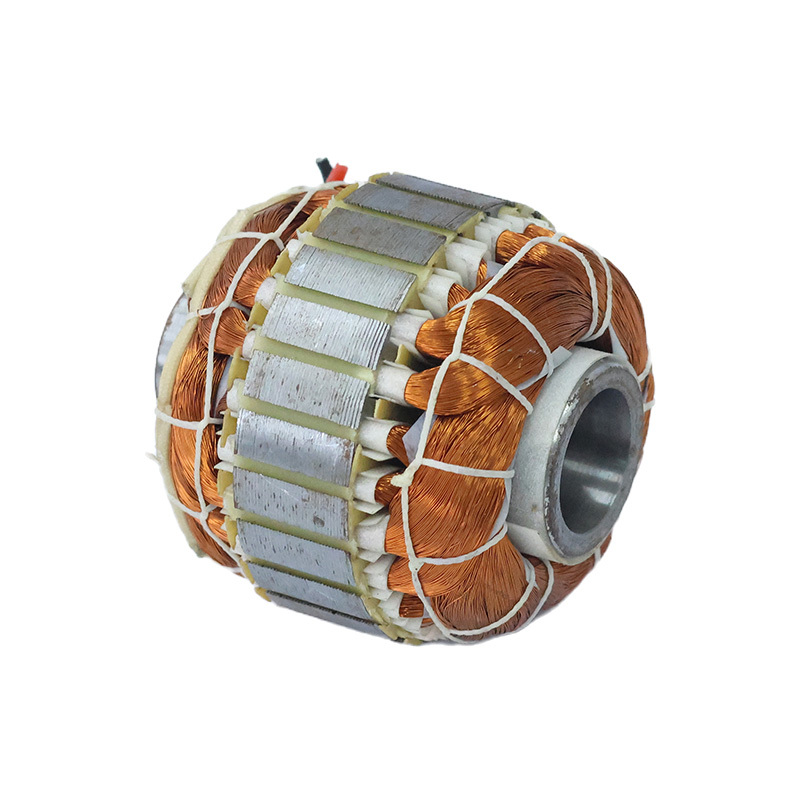

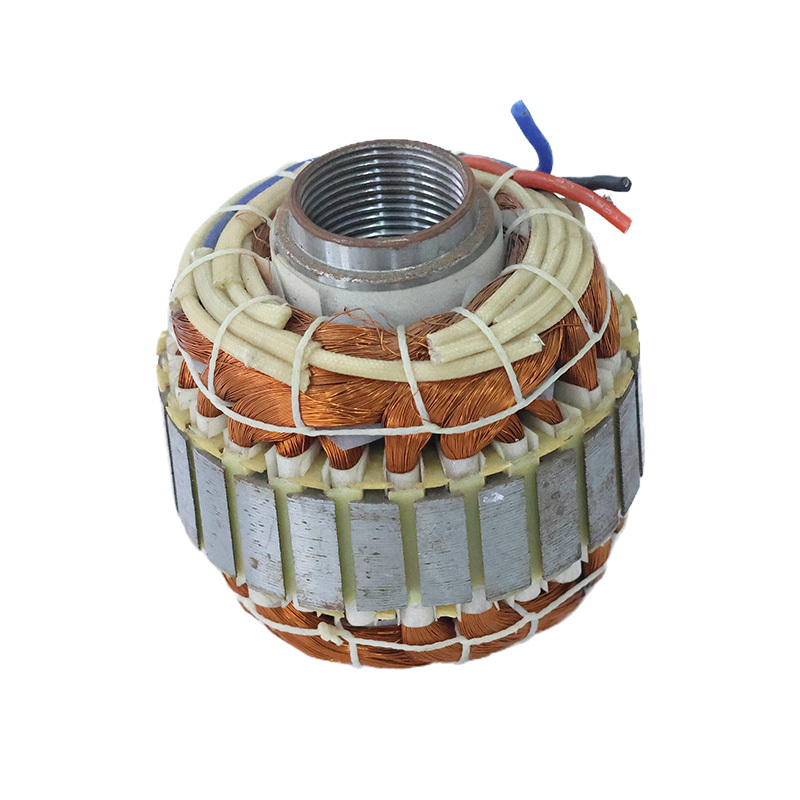

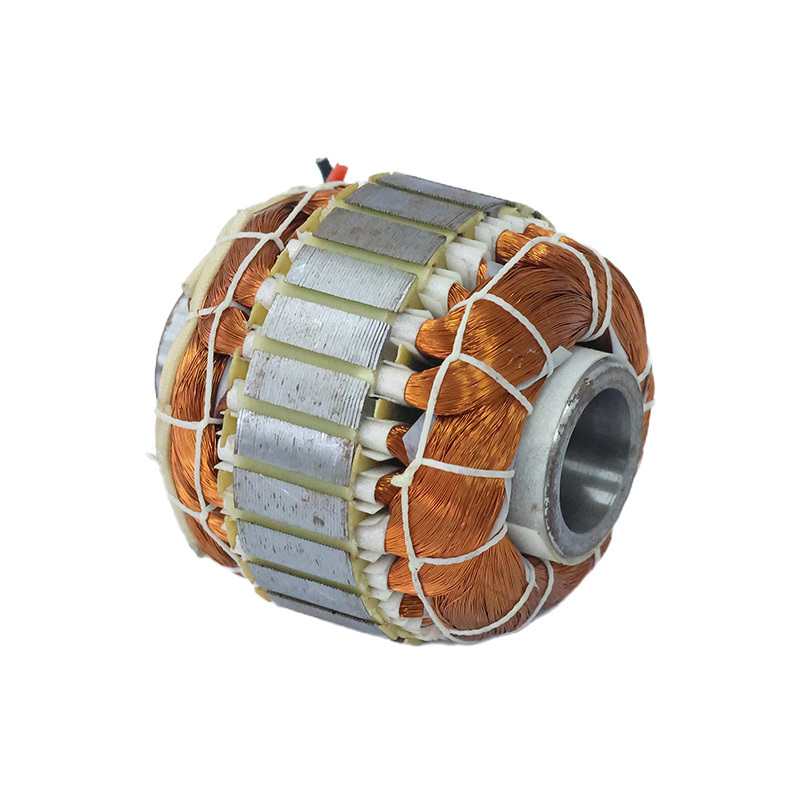

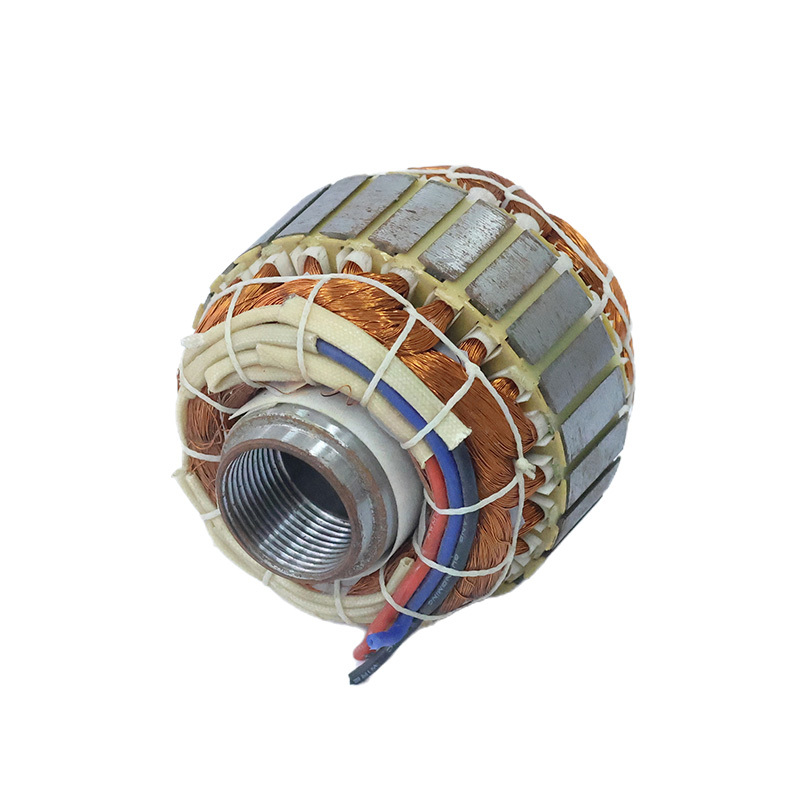

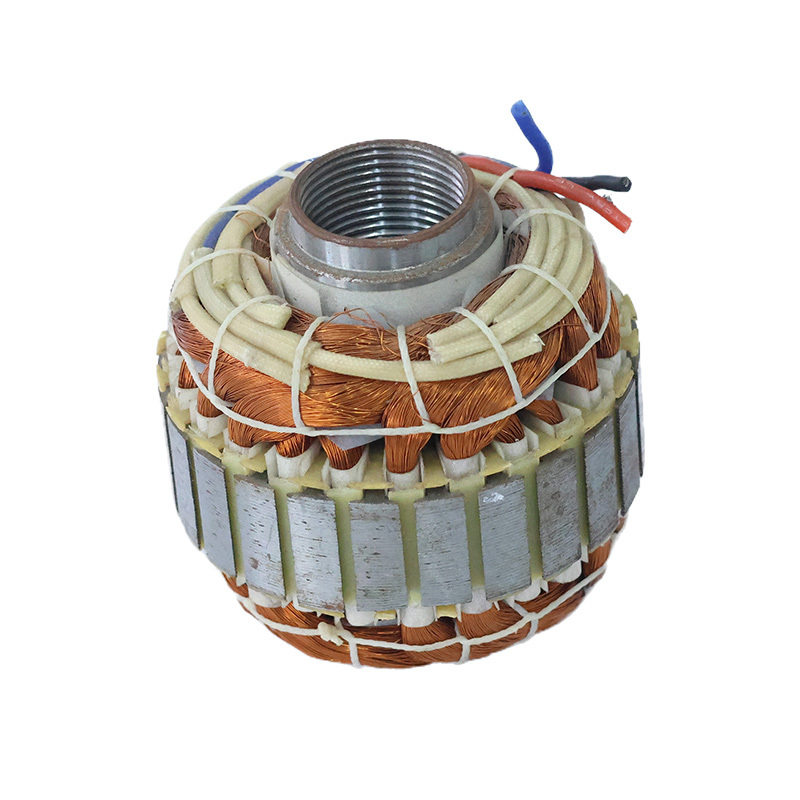

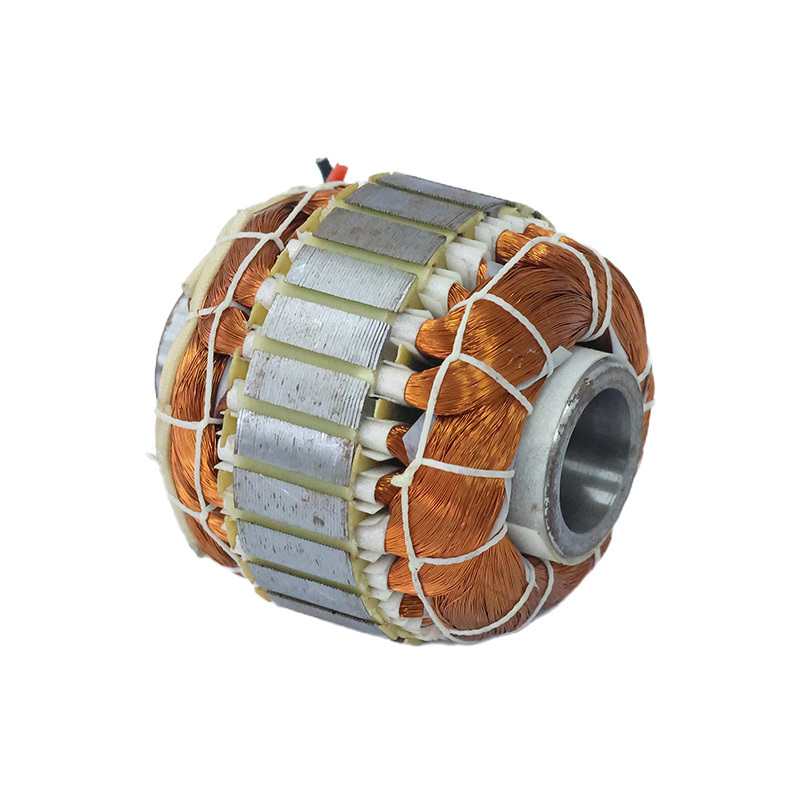

CXK(2025) High Quality Alternator Stator Coil Assembly OD92 ID45 SLOT12 Motor Generator Accessories for Mixers Made in China

Our company mainly engages in various types of motor coils, winding, embedding processing, and has the ability to assemble and manufacture stator assemblies through manual embedding, machine embedding, immersion painting, and so on.

Key words:

CXK(2025) High Quality Alternator Stator Coil Assembly OD92 ID45 SLOT12 Motor Generator Accessories for Mixers Made in China

Classification:

Stator assembly

E-mail:

Conditon | 100% brand new | |

Advantage | High-quality ,Factory Price | |

Manual measurement error | Tolerance of about 2mm is normal | |

Certificate | IOS9001 | |

Size | Non-standard sizes can be customized according to your requirements | |

Finish | Plain,qalvanized/according to your requirements | |

Top quality, very durable and in good working condition. | ||

Samples can be provided for reference, support batch customization | ||

Sincerely look forward to cooperating with you | ||

The stator assembly is a key component in the motor, which consists of windings, stator core and stator slots. Reasonable design and manufacturing can improve the efficiency of the motor and reduce energy loss. In the manufacturing process of the stator assembly, attention to detail is required to ensure the stability and reliability of the stator assembly. The layout of the winding includes the number of layers, turns and slots of the winding. Reasonable layout can improve the efficiency of the motor, reduce harmonics and noise. The windings are usually fixed in the slots of the stator core by insulating glue or insulating paper to ensure the stability and reliability of the windings.

Distinguished by the shape of the stator winding and embedded wiring method

Stator winding according to the shape of the coil winding and embedded wiring is different, can be divided into two types of centralized and distributed.

1. Centralized winding

The centralized winding generally consists of only one or several rectangular frame coils. After winding, it is wrapped and shaped with yarn tape, and then embedded in the core of convex pole after dipping and drying. DC motor, general-purpose motor excitation coil, as well as single-phase shaded-pole motor main pole winding are used in this winding.

2. Distributed winding

Distributed winding motor stator without convex pole palm, each pole is one or several coils in accordance with a certain law embedded wiring coil group. According to the different forms of embedded wiring arrangement, distributed winding can be divided into concentric, iterative two types.

(1) Concentric winding

Concentric winding is the same coil group of several rectangular coils of different sizes, according to the same center of the position of the embedded one by one arranged in a zigzag pattern. Concentric winding is divided into single layer and multi-layer. General single motor and some small power three-phase asynchronous motor stator winding using this type.

(2) Iterative winding

Iterative winding is the shape and size of all the coils are exactly the same (single and double turn exception), respectively, to each slot embedded in a coil edge, and in the groove at the end of the outside of the phase by phase evenly distributed type. Iterative winding is divided into single-layer iterative and double-layer iterative two kinds. In each slot only embedded in a coil edge for a single layer of iterative winding, or single iterative winding; each slot embedded in two different coil groups of coil edge (divided into the upper and lower layers) for the double layer of iterative winding, or double iterative winding. Iterative winding due to the embedded wiring changes in different ways, there are single and double circle cross wiring arrangement and single and double mixed wiring arrangement of the points; in addition, from the end of the winding embedded in the shape known as the chain winding, basket winding, in fact, are iterative winding. General three-phase asynchronous motor stator winding is more often used iterative winding.

Changzhou CXK Motor Company is located in Changzhou City, Jiangsu Province, with a distance of about 171.8 kilometers from Shanghai Hongqiao Airport. We established in 2017, it covers an area of more than 10,000 square meters and has a staff of over 160 people, with annual sales of over 25 million yuan.

CXK Motor Company mainly engages in the production of various motor components, including stator winding, motor stator assembly, motor housing, motor shaft, end cover, rotor and stator core, cast iron parts, winding, cast aluminum parts, and other motor accessories, Our products are exported to all over the world especially: Netherlands, the United States, Spain, etc. and we are highly trusted and praised.

CXK motor components are applied for various mechanical industries, including AC motors, DC brushless motors, stepping motors, and servo motors, covering automobiles, mechanical equipment, refrigeration equipment, electrical appliances, and electric vehicles. We have unique advantages in customize motor parts and can provide tailor-made solutions for customers. Thanks to our complete motor production equipment, we have large production capacity and significant price advantages. We own strong R&D capabilities, following market trends and customer needs closely can meet various order quantities.

CXK Motor Company has passed ISO 9001 quality management system and strictly adheres to high quality standards in production. We adheres to the principle of starting from customer needs and ending with customer satisfaction, and continuously improves product value and enterprise image with high-quality products and high-quality after-sales service.

Sincere cooperation, foresight for the future!

Q1: What kind of company are you?

A1: We are a motor company integrating industry and trade, specializing in the production of various

motor product accessories and possessing 20 years of manufacturing experience

Q2: Are all your products in stock?

A2: Normally, our products are customized and we seldom keep them in stock. If samples are needed, we can send some. Generally, we are required to customize and produce according to the customers' requirements to meet their different needs.

Q3: What is your minimum order quality?

A3: We don't have a MOQ requirement. We produce according to customers' orders, and we can meet different needs regardless of the quantity.

Q4: How do you make our business long-term and good relationship?

A4: Firstly, we keep good quality and competitive price to ensure our customers benefit, Secondly, we respect every customers as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q5: Do you accept small orders?

A5: Feel free to contact us. In order to give our clients more convenience, we accept small order We can also send you the samples if you want.

Q6: Can you do OEM for me?

A6: We accept all OEM and ODM orders, just contact us. we will offer you a reasonable price and make samples for you ASAP.

Q7: What is your terms of payment?

A7: Normally 30% in advance and balance should be paid off before delivery goods. But if for long term cooperation, we can accept other payment conditions.

Products Description

Product Message

Other Products