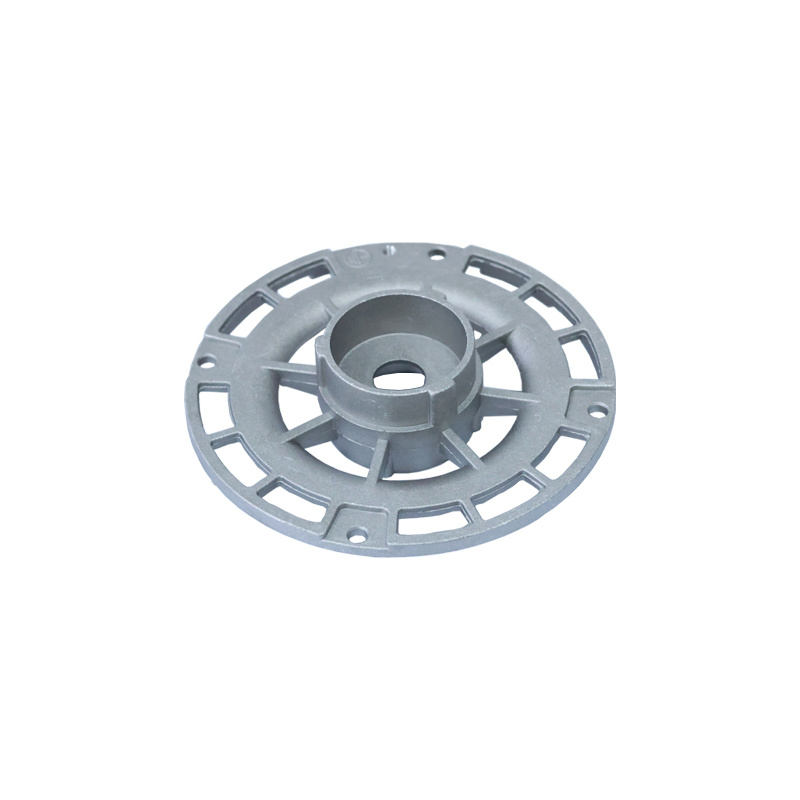

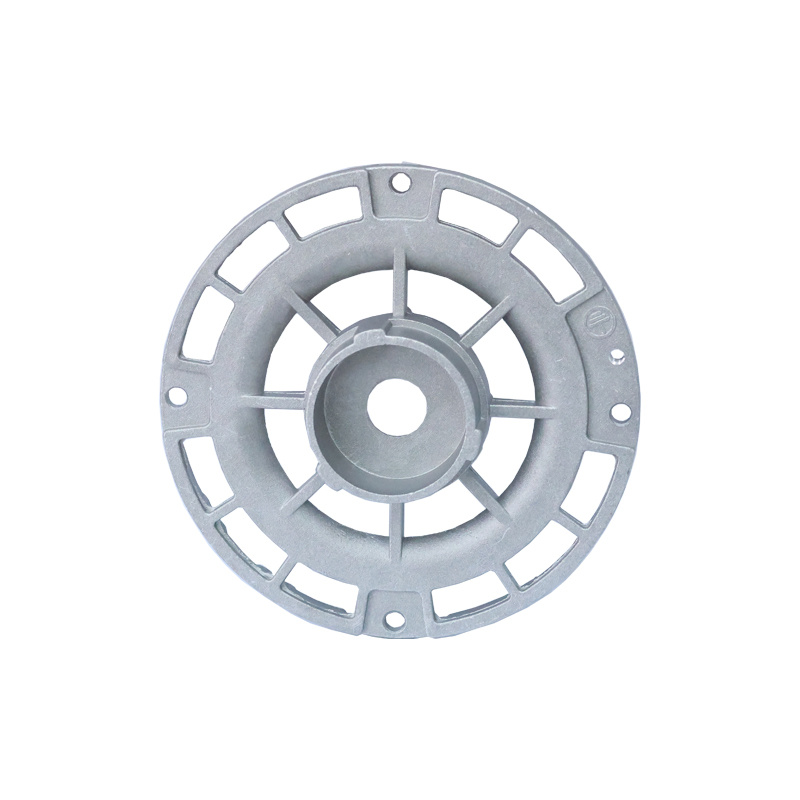

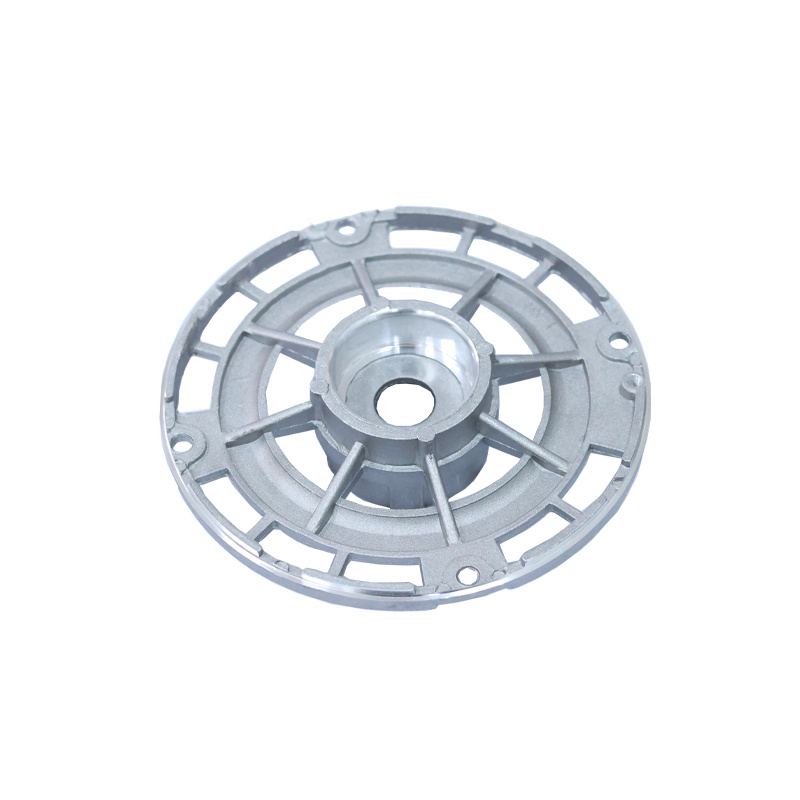

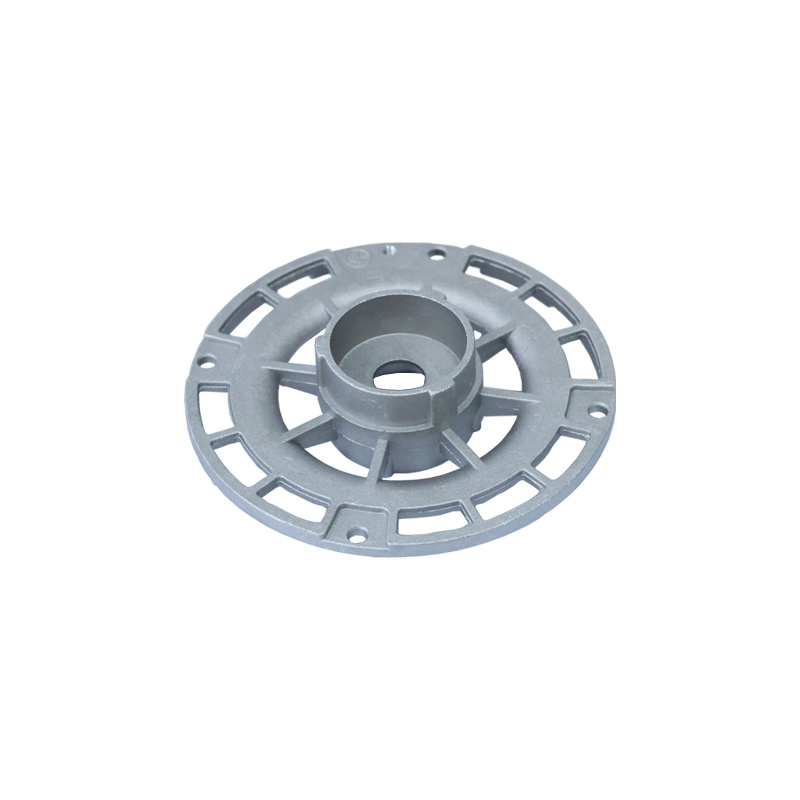

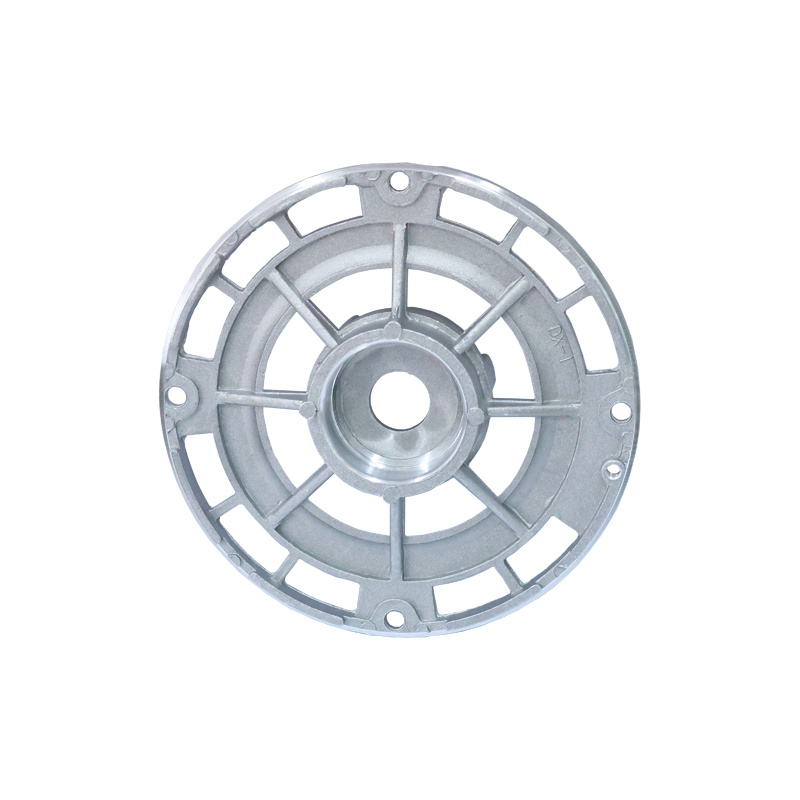

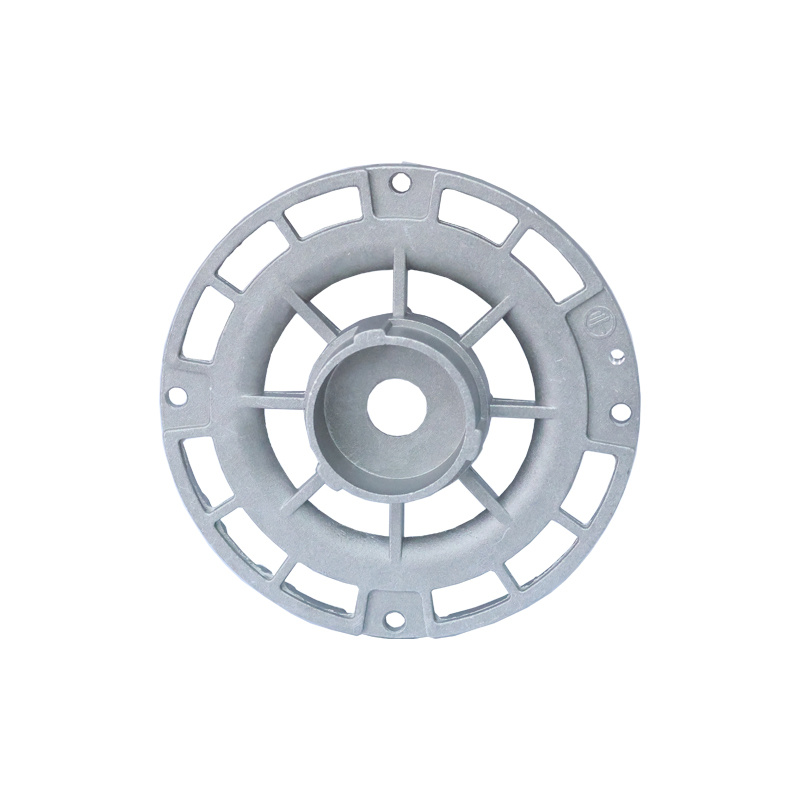

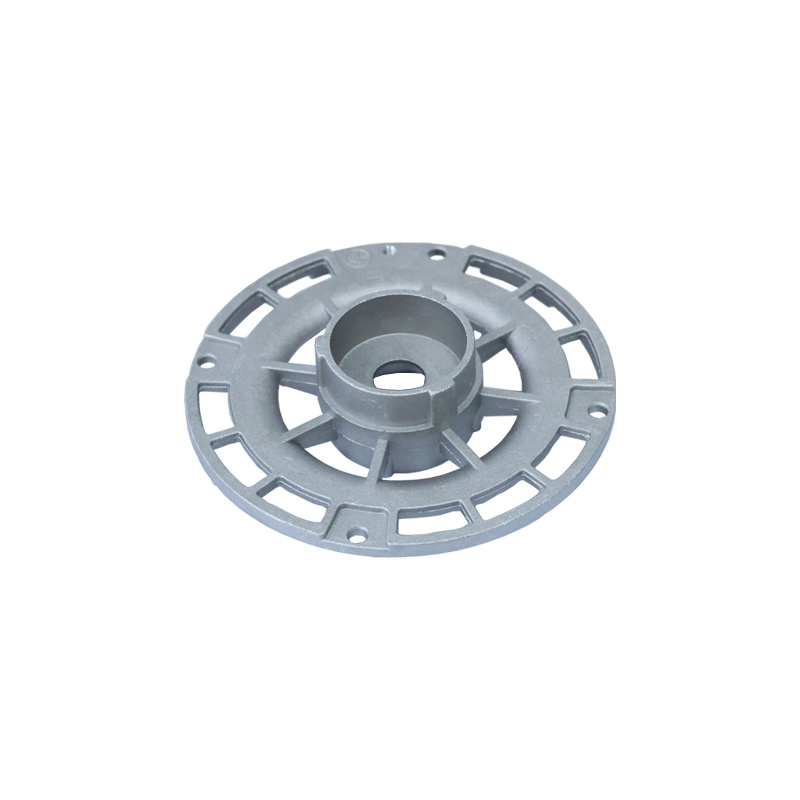

Use of motor end caps

CXK(2025) China Jiangsu Supplier Aluminum Die Casting Motor Housing Motor End Cap, ADC12 Material for Fan Motor.

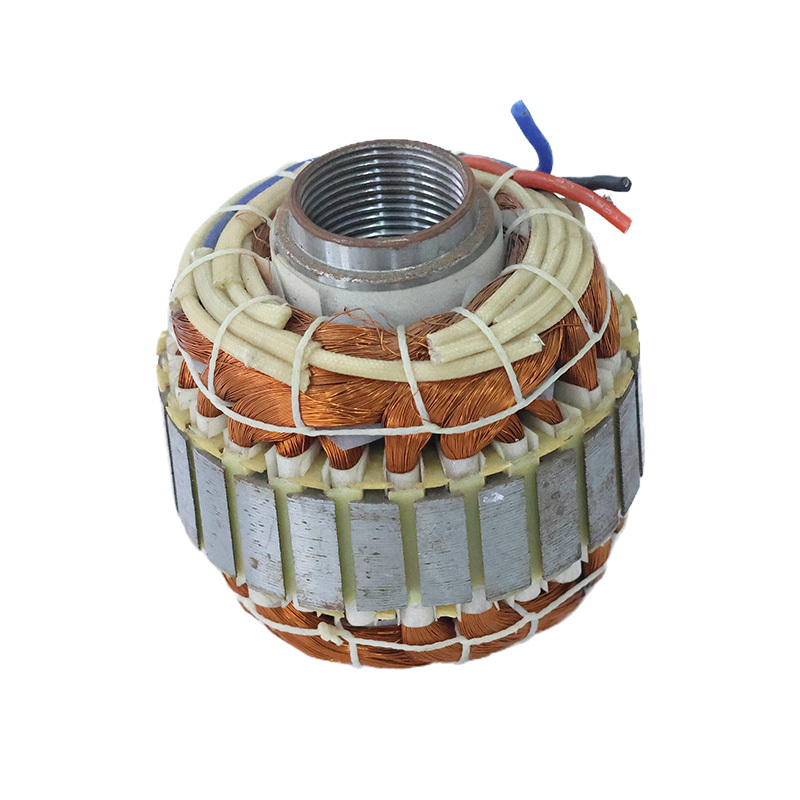

Our company mainly engages in various types of motor coils, winding, embedding processing, and has the ability to assemble and manufacture stator assemblies through manual embedding, machine embedding, immersion painting, and so on.

Key words:

CXK(2025) China Jiangsu Supplier Aluminum Die Casting Motor Housing Motor End Cap, ADC12 Material for Fan Motor.

Classification:

End cap

E-mail:

Brand Name | CXK |

Place of origin | Jiangsu, China |

Makings | ADC12,ZL102 |

Certificate | IOS9001 |

Model number | Can be customized according to customer requirements |

Process | Casting+Machining(If Need)+surface |

Size | Can be customized according to customer's needs |

Service | OEM \ ODM |

Sales unit | Piece/Pieces |

Design 3d Mould Drawing | • Our engineers will design the 3D mold drawing for your confirmation. • Design software: CAD, etc • Surface Finish: Polished or semi-matte |

Motor End Cap

Motor end cover: it is the cover of the motor casing. Generally divided into front cover and rear cover, used to fix and support the motor rotor shaft. End cover generally refers to the axial size is greater than the radial size of the motor ends of the cover, the main role is to determine the spatial location of the rotor's shaft, of course, need to cooperate with different forms of bearings, through the end of the cover is connected to the fixed motor stator shell, to ensure that the gap between the rotor and stator, generally cast iron process, the small motors can also be sheet metal stamping molding.

In common parlance, the front and rear end caps of the motor are utilized to secure the entire motor by means of a rotating shaft. Motor end caps are a necessary accessory for motors and are used in a wide range of applications. Usually for the following: Car air conditioner, car fan, heater and so on. Motor end caps generally have some concave and convex holes on the shape, one is used to enhance the motor heat dissipation, and the other is to enhance the mechanical strength of the motor.

Most of the industrial motor end caps are made of cast iron, which serves to support the bearings at both ends of the motor. The

main role is to fix the motor rotor, piggybacking on the role of heat dissipation. Generally made of cast iron, there are some one

kilowatt motor with cast aluminum.

main role is to fix the motor rotor, piggybacking on the role of heat dissipation. Generally made of cast iron, there are some one

kilowatt motor with cast aluminum.

Motor End Cap Material

Motor end caps are generally made of metal, including aluminum, aluminum casting, cold-drawn steel, plastic, and plastic wood. Generally according to different types of motors to choose different materials. For example, automobile motors are mostly cold-drawn steel, and large motors use die-casting.

Surface treatment of motor end caps

The surface treatment of the motor end cap directly affects the life of the whole motor, usually in the following ways: 1、Blackening treatment 2、Galvanized treatment 3、Painting treatment 4、Dacromet plating treatment Generally speaking, the blackening process is the worst, the lowest cost, and vice versa.

Changzhou CXK Motor Company is located in Changzhou City, Jiangsu Province, with a distance of about 171.8 kilometers from Shanghai Hongqiao Airport. We established in 2017, it covers an area of more than 10,000 square meters and has a staff of over 160 people, with annual sales of over 25 million yuan.

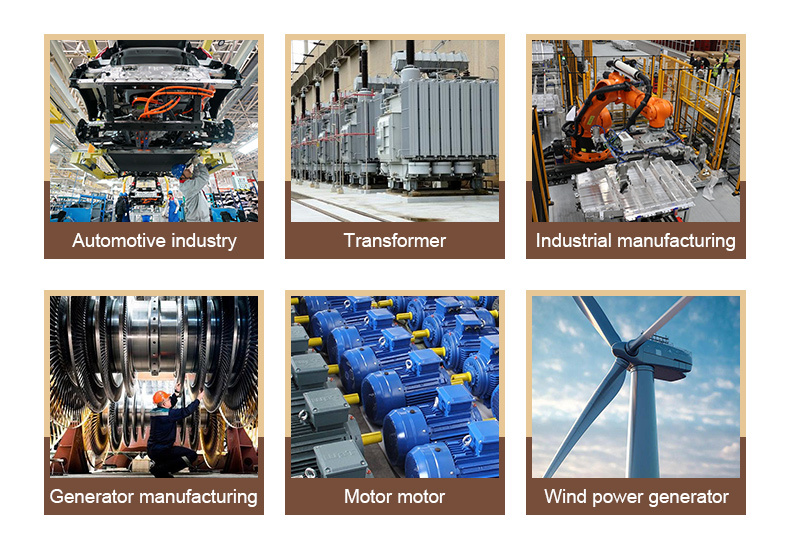

CXK Motor Company mainly engages in the production of various motor components, including stator winding, motor stator assembly, motor housing, motor shaft, end cover, rotor and stator core, cast iron parts, winding, cast aluminum parts, and other motor accessories, Our products are exported to all over the world especially: Netherlands, the United States, Spain, etc. and we are highly trusted and praised. CXK motor components are applied for various mechanical industries, including AC motors, DC brushless motors, stepping motors, and servo motors, covering automobiles, mechanical equipment, refrigeration equipment, electrical appliances, and electric vehicles. We have unique advantages in customize motor parts and can provide tailor-made solutions for customers. Thanks to our complete motor production equipment, we have large production capacity and significant price advantages. We own strong R&D capabilities, following market trends and customer needs closely can meet various order quantities. CXK Motor Company has passed ISO 9001 quality management system and strictly adheres to high quality standards in production. We adheres to the principle of starting from customer needs and ending with customer satisfaction, and continuously improves product value and enterprise image with high-quality products and high-quality after-sales service. Sincere cooperation, foresight for the future!

Q1: What kind of company are you?

A1: We are a motor company integrating industry and trade, specializing in the production of various motor product accessories and possessing 20 years of manufacturing experience

Q2: Are all your products in stock?

A2: Normally, our products are customized and we seldom keep them in stock. If samples are needed, we can send some. Generally, we are required to customize and produce according to the customers' requirements to meet their different needs.

Q3: What is your minimum order quality?

A3: We don't have a MOQ requirement. We produce according to customers' orders, and we can meet different needs regardless of the quantity.

Q4: How do you make our business long-term and good relationship?

A4: Firstly, we keep good quality and competitive price to ensure our customers benefit, Secondly, we respect every customers as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q5: Do you accept small orders?

A5: Feel free to contact us. In order to give our clients more convenience, we accept small order We can also send you the samples if you want.

Q6: Can you do OEM for me?

A6: We accept all OEM and ODM orders, just contact us. we will offer you a reasonable price and make samples for you ASAP.

Q7: What is your terms of payment?

A7: Normally 30% in advance and balance should be paid off before delivery goods. But if for long term cooperation, we can accept other payment conditions.

Products Description

Product Message

Other Products